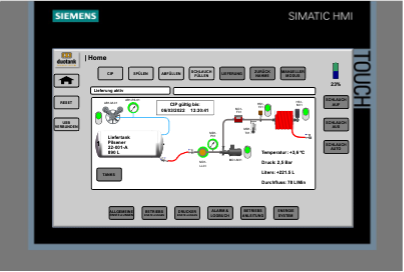

The control panel allows you to enter how much beer should be delivered and to which customers. The pump starts/stops pumping via a button on the remote control. The HVLP compressor starts automatically to maintain enough pressure in the (transport) tanks. Once the desired quantity is reached, the pump automatically shuts off and the valve closes.

The delivery note can be printed and stored digitally in a MID-certified memory. The layout of the document is customizable. Customer-specific data such as customer name, beer type, etc. can be added. Optionally, the delivery data can be saved in a CSV file. This file can be specifically configured, e.g. for quality control and traceability. Additionally, there is the option to connect the CDU to the cloud via an MQTT server. In this case, delivery data and, if necessary, truck location data can be sent to the cloud.

If there is air in the line, the electric butterfly valve automatically closes to prevent incorrect measurement. In the event of a power failure, the butterfly valve also closes automatically. The emergency power supply ensures that all beer flowing through the flow meter is counted until the valve is fully closed.